HyFilm® LEO Extends Drain Cycles Four to Five Times

HyFilm® LEO 5W40 Engine Oil Extends Drain Intervals

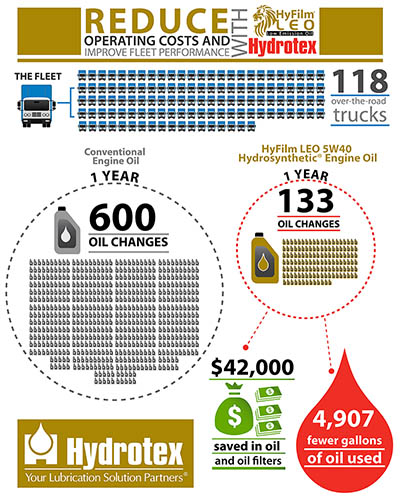

Hydrotex® Lubrication Reduces Operating Costs and Improves Fleet Performance

Nebraska Transport Company (NTC) based in Scottsbluff, NE offers truckload and less than truckload carriage and transportation services. NTC in conjunction with Hydrotex developed a collaborative process to reduce bottom line costs and implement a condition-based maintenance program.

John Beasley, President and CEO of Hydrotex stated, “We were pleased to partner with Nebraska Transport Company and collaborate to develop and implement sustainable solutions. Through our national network of trained representatives, we are committed to providing our customers with practices and products designed to enhance sustainability of their operations.”

NTC uses HyFilm LEO 5W40, Hydrosynthetic® Engine Oil in all of their vehicles and the average drain cycle has been extended four to five times over the historical average. The fleet of over 118 over-the-road trucks required 600 oil changes annually when using conventional oil; with HyFilm LEO Engine Oil, change intervals now average approximately 133 per year. Net savings realized from oil and oil filters alone averages over $42,000 per year with 4,907 fewer gallons of engine oil used. In addition, savings do not reflect the mileage efficiencies realized by converting to a low viscosity synthetic engine oil.

Oil analysis is performed on all vehicles and is used to identify potential problems and optimize maintenance intervals. This analysis has proven to be a very effective tool for a condition-based maintenance program.

U Joint failures were another problem NTC was experiencing. By converting to Hydro-Syn 70 NLGI #2, a Hydrotex grease appropriate for this specific application, the service intervals were increased from a historical nine month service life to an average life of 2.5 years. The annualized savings exceeds $31,000.

With terminal operations in Nebraska, Colorado, Iowa, Kansas, Illinois and the Dakotas the NTC fleet faces severe climate changes with hot summers and cold, snowy winters. The winter months present a unique set of challenges when costs for stranded trucks due to icing, gelling and plugged fuel filters occur. Fuel analysis combined with the use of Power-Kleen™ Arctic fuel improver has essentially eliminated these expenses that can exceed $1,000 per stranded truck.

Brent Holliday, CEO of Nebraska Transport Company, sums up the relationship, “Our long-term partnership with Hydrotex and our local Hydrotex Division Partner has been very successful.

Not only are we protecting our equipment with high performance synthetic lubricants, but we have implemented a Lubrication Management Process to reduce operating costs, increase ROI and reduce our carbon footprint. In addition, our Fuel and Oil Analysis programs provide critical information regarding the performance and endurance of our equipment while establishing a roadmap to quality short-term and long-term maintenance planning.”